Tuesday... Really getting underway

Monday afternoon consisted largely of making coil winders, doing some blade carving practice on unfinished and/or blemished blades from previous years. There was also some work getting molds for stators and rotors, and some welding practice.

Tuesday morning got an early start... Here Renee winds a coil while somebody else looks over and counts. Not so easy to count the exact number (250+) of windings while turning the crank.. helps to have someone else keeping tabs as well. Note DanB in the background cutting blade tapers.

Here the local woodworking volunteer instuctor B.J. gives some pointers in proper technique.

Hugh looks over a practice blade being smoothed.

Gabriel hacks away with a draw knife...

Hugh generally prefers hand tools... DanB knew this in advance, and brought out his own power planer. Depending on the wood though, it really isn't necessarily faster than the draw knife.

Here, the coils for one machine have been wound. Then they are weighed in order to be sure they are consistant.

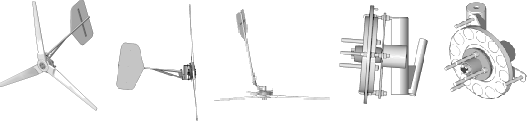

Outside, folks were busy working on molds for the stator and in this case, a rotor.

Here folks get some practice and instruction welding from Andy who is another of the local expert volunteers.. The actual parts for the frame of each machine have to be cut out of angle iron, so until that is done, its practice.

The mold for the stator of the large 12" machine is just about finished, and the coils are place within to make sure they fit as planned.

Assembly beginning on one of the two machines... Betsy welding bits together. She is very competent welder, and was willing to do so whenever the need arose. Who can blame her... its so much fun.

Seen here is Doug. He is also a local volunteer, and a really neat guy. In the end, he will get the smaller (8') generator for his own use.

Um... here is me. Apparently someone borrowed my camera. I did actually do a little bit of work.

Making the solder connections for the coils... can't mess that up, as those connections will eventually be buried deep within the fiberglass resin of the stator.

That was about the end of the work on Tuesday. Later in the evening there was a casual seminar about power systems...inverters and the like, by Chris from Outback Power Systems. There was a gathering at cabin #6 thereafter.

And, be sure to check out our book Homebrew Wind Power for more small wind power information!

Click Here to get back to the front page.

Click Here to get back to Monday pictures.

Click Here to move on to Wednesday pictures.