Large scale hydroelectric power has been used worldwide for a long time to generate huge amounts of power from water stored behind massive dams. Small scale hydropower has been used for hundreds of years for manufacturing, including milling grain, sawing logs and manufacturing cloth. However, it can also be used without a dam to generate electricity for home scale remote power systems. These so-called micro-hydro installations can be a very good complement to a solar power system, as they produce electricity 24 hours a day.

Waterwheels--It's important to differentiate between water wheels and water turbines. A water wheel is more akin the antique version we are all familiar with--a massive wooden wheel that slowly turns as the creek pours down over it. Water wheels spin slowly, but with lots of torque. They are not particularly efficient, but can be very effective. Even a few watts of power coming 24/7 can help an off-grid power system immensely. There are only a couple of places specializing in water wheels and water wheel info, and both are excellent resources: The Waterwheel Factory and The Waterwheel Place. The latter also has a good waterwheel electrical output calculator HERE.

Scotty's new homebrew hydro plant, using a Banki Turbine design built from scratch. The generator is a homebuilt permanent magnet alternator, very similar to our Brake disc alternators. In a Banki design, the water hits the vanes twice, once upon entrance and then again upon exit. There is only about 4 feet of head available at the site, and the system is producing about 2 amps at 12VDC, fed by a 4 inch pipe.

A while back, one of our neighbors constructed a water wheel generator using a squirrel cage fan, belt, pulley and surplus tape drive motor that produced a steady 1 amp of power, 24 hours a day. He used a natural dam (a log that fell across the creek years ago) to get the fall and to mount the generator on.

Some General Micro Hydro Power Information

NOTE -- as you can see from the photos and web pages linked to above, we don't have much of a hydro power resource here. The crick is very small, often dries up in the summer, and freezes nearly solid in the winter. So we are not the best place to direct your hydro power questions to, we have hardly any hydro experience. There are some great sites listed in our Hydro Power Links section.Turbines--All of the commercial micro hydro generators available today use a small turbine connected to an electrical generator or alternator. Water is collected in an intake pipe upstream, travels down to the turbine in plastic pipe, and is forced through one or more nozzles by its own gravity pressure. No dam is needed; systems without a dam are called "run of river" systems. Power is generated by a generator or alternator directly connected to the turbine wheel (no gears or pulleys needed). All of the factors below must be calculated correctly for your micro-hydro equipment to make power most efficiently. All commercial micro-hydro setups are custom-made by the manufacturer for your specific application. For proper operation, you must supply the manufacturer with specific data about your site, most importantly the vertical drop in feet (called "head"), the amount of water flow available during different seasons in gallons per minute, and the length of pipeline required to get a sufficient head.

- In general, for a water turbine you need at least 3 feet of fall and at least 20 gallons per minute of flow. If you have more fall (head), less water is required. You can calculate potential head with a water level, a contractor's level and stadia rod, or with just a string level attached to a measuring stick. The more fall and flow that you have, the more potential power you can generate. You can measure flow by building a weir in the creek and measuring how fast it will fill up a 5 gallon bucket.

- Your pipeline must be of a big enough diameter to minimize friction loss in the pipe. Your micro-hydro supplier can give you specific information regarding this.

- Nozzle size and turbine wheel type are all interrelated to your total head and flow. Again, your hydro supplier will customize these for your specific application. Often, different size nozzles are designed to be switched in and out as stream conditions change throughout the year.

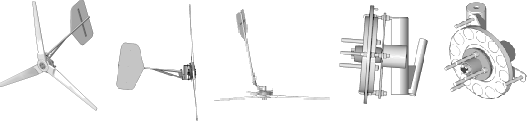

- There are two main types of turbines, impulse and reaction. With impulse turbines, a jet of water is created by the nozzle and squirted onto the wheel. Reaction turbines are more akin to propellor that spins INSIDE the pipe, generating power.

- The 3 primary impulse turbine wheel types are Pelton, Turgo, and Cross-flow. Pelton wheels are used in low flow, high head conditions, and Cross-flow wheels are for high flow, low head installations. Turgo wheels are somewhere in the middle. Francis and propellor turbines are the most common reaction type; the Francis design is very similar to the innards of a centrifugal pump. A Kaplan turbine is also similar to this design.

- Home built reaction turbines have been built using centrifugal pumps running in reverse (generating power with moving water instead of using power to move the water). We hope to have more information about experimenting with this soon. You can buy a book about from ITDG books, they also have a book about using induction motors as generators for micro hydro power.