Trip to Vanua Balavu

Part 2; Tears, Blood and Sweat, the upgrading of a small computer lab

Upon Arriving at the airport, well air strip on Vanua Balavu, which is interesting because it is on the side of a hill, we got a ride out to our lodging, which was at Moana's Beach House. This beach house is run by the Fotofili Family. There daughter Moana, is a student at the Andi Malpa Secondary School . We were provided with lodging by them for our mission, and in addition, we upgraded some of there solar systems, and Ben brought a new bicycle out to them, which is apparently hard to get on the island.

We unloaded our luggage and settled into a hut that was built by Richard Cross when he had visited the island in the past. Richard Cross is the fellow who first brought Ben out there to do volunteer work. The hut is right on the ocean. At high tide, you are but a few feet from the waves.

This is a blurry picture of the hut where we stayed. The ocean was right off to the left. The blurry blue square on the thatch is a 10 watt solar panel that charges a battery. Since the hut is not always in use, this is sufficient to keep the battery charged. The hut had a fluorescent light that was powered from the system, and Ben brought a 12V portable shower which we wired up as well. I also brought a small inverter which I used to charge my camera and phone battery, at least until my phone got a little too close to the ocean. To the right in the photo was my alarm clock.

A better picture of the alarm clock, it required no batteries or winding, and was very, very persistent. I was thinking of introducing him to an old friend I happened to bump into in Suva, Fiji below. . .

Actually though it was a good thing to get up at the crack of dawn. Since there is limited power for lighting, it is good to use as much of the daylight as possible.

We upgraded a couple of the small solar systems that they had at the guest house for the kitchen and the hut where we stayed. We had dinner at the Fotofili's and settled in for our first night on the island.

This was one of the new control panels that Ben had built for this trip. This one was installed in the hut we were staying in.

After breakfast and a little work at the Fotofilli's we headed into the school to start work on the project. Ben was a bit disappointed that the work shop he had assisted in sitting up the prior year was not being utilized. He also noticed that some of the tools and equipment were not in the workshop. Some of these tools found there way back there during the course of our stay, as they were being used for other purposes.

I was tasked with building a rack for the solar panels and placing them on the roof. Apparently Ben had promised his wife Cass that he would not climb on the roof of the school during the trip. . . In spite of my best efforts, he did keep that promise.

Ben had been there the prior year, and at that time the plan had been to mount two of the panels on the school for the computer lab, and one at the workshop. The idea had been that the panels would be mounted shortly after Ben left the in 2006. This had not happened, perhaps in part because the alternator had gone out on the school's generator and the solar panels had been used to charge the starting battery. In fact we wound up using one of the 20 watt panels that I had brought to keep that battery charged for the near term.

There was not much metal available to make a frame from. There was a frame welded out of an old motorcycle pallet the prior year to mount two frames, and a few scrap pieces left over from the pallet and a bit of rebar. We now had three 40 watt panels and two 20 watt panels to mount for the computer lab. I climbed up on the roof with one of the vocational students to take measurements so I could figure out what to build.

There was a nice view from the roof. The school grounds is right on the ocean, as is almost everything here. I took this shot one evening up on the roof. It is all ocean from here to South America out there.

I decided to take the previously made frame apart, and put together one frame to mount the panels on. With the help of some vocational students from the school, we took the old frame a part, and slowly made the pieces of the new frame. You really, really appreciate power tools when you have to use a hand drill, and a hacksaw to cut and drill the pieces.

students preparing a piece of metal which became part of the frame.

All of the pieces had to be cut by hand.

We all took turns working on parts. In this picture the principal is drilling a hole in what would become one of the mounting feet for the rack.

It took us about a day and a half to do what I could have done back home in a few hours with power tools.

While we were working, classes were in session. I tried not to interfere with the classroom activities. You would here choir singing sometimes, which was kind of neat, and whenever they could see you, it seems like the students were curiously watching you work. Everyone was very polite.

Here some students were giving oratory presentations on the field in front of the school.

Each day, the staff at the school prepared a nice lunch for us. It was an interesting cross section of the local foods, many of which I had never had before.

Here was one of the lunches prepared each day for us. In this case there was Bread and baked beans, fish, local fruit, and a root crop called taro. Also, be wary of those tiny peppers on the plate. They could be squeezed into a bottle and be effectively used directly as pepper spray I do believe. I drank pretty much only Coke and Diet Coke the whole time there. I had read about Ben's stomach discomfort from his last trip and did not drink any local water in an effort to avoid getting sick.

I probably made a dent into the supply of soft drinks at the general store in Lomaloma which is pictured above, but I didn't get a stomach ailment while in Fiji.

Meanwhile, Ben was working on getting the computer lab, and the laptops into shape. The dump load controller from the prior year was fried. The only thing we could figure that happened was that the batteries were disconnected when the mill was running and that the voltage got really high. The LM317 was just about vaporized and the control board was severely scorched.

I bet that let out a bunch of that magic smoke that Ghurd warned me about.

The computer teacher had connected the computers from the last trip to the higher voltage and the power supplies in those were beyond our ability to repair on the island. Ben had brought a new dump load controller board and dump load that he had made, and set about repairing these items. He also had assistance from some of the students and staff. Ben also rigged the breakers such that the mill now can not be connected with the batteries disconnected. Since there had been nothing charging the battery, it was completely dead. For two days we tried various methods to get some power into it, but it would not hold a charge. We wound up swapping it with the smaller battery in our hut, at least for now.

The smaller battery in place. Temporarily no power in our hut though :-(

We had arranged for an about 70 amp hour or so battery to be shipped from the main island to the Fotofilli's prior to leaving for Vanua Balavu. So hopefully it got there and the hut is powered up again.

We ran a cord from the village water pump, which is diesel and also has a generator head so that we could start welding. When the schools diesel generator was running after dusk, we were able to use power from that. We would connect an inverter type welder that Ben had brought out there the prior year and weld the frame together. Master Singh, one of the teachers there helped me out. There was another fellow there, I forget his name, who was a plumber, and it turned out he could weld pretty well. Once we had the frame assembled, we put a coat of paint on it.

Master Singh welding on the frame.

The frame nearing completion. It is canted at about 20 degrees to the north, about right for this latitude, and was made to fit the roof pitch.

The next day we mounted the frame on the roof, bolted it into the rafters. Unfortunately one of the welds to the rebar broke. It was not easy to get good welds to the rebar, and I still have a bit of concern about those welds.

At night when the generator was running we scrambled to find enough cords to stretch power to the roof to weld. We fixed the broken weld, and did a little supplemental welding on a bit of the rebar to strengthen the welds.

The next morning we mounted the panels to the frame. I should have only brought one student up at a time. While we were up there, one of the students dropped a water bottle which rolled down the roof. He tried to catch up with it and grab it before it went over the edge. Ben saw it from below, and yelled at the boy to stop as he was running. Fortunately he did not go over the edge, but it was close enough to give me a good fright.

Bolting the solar panels to the frame.

Next we wired the panels into the control board. The panels are all connected in parallel to charge at 12 Volts. We fished the cables through some old water piping to protect it from the weather for the exposed part of the run. We left off one of the 20 Watt panels, which we later temporarily mounted on the roof of the generator shed to keep its starting battery charged until we can get an alternator out to it. Even without that panel, the array fed about 10 amps into the battery in full sun.

The Solar panels mounted on the roof, with the exception of the one 20 Watt panel we temporarily mounted on the generator shed. We left a pigtail on the frame to attach it once the alternator is installed on the generator.

Meanwhile, back down in the computer Lab, Ben was showing the computer teacher, Virginia, the features of the new laptops. The laptops were fitted with cords that would connect them to the power distribution box. The laptops only drew about an amp apiece, or around 6 amps with all six running. The solar panels alone could more than keep up. The new dump load and its controller that Ben built were working well now that the tropical sun was able to rapidly charge the battery.

Newly repaired control panel with the new dump load mounted above. Ben was sure to post conspicuous instructions for the panel. I received an e-mail from Rehanna, the science teacher when she visited the main island recently indicating that the panel and dump load were still working flawlessly.

Virginia, the computer teacher, happily looking over the upgraded computer lab.

On Saturday, the day before we left, we arranged to lower the wind turbine to service it. The cables were anchored to loops made of rebar that were welded to pipe that was buried in concrete. The lowering of the tower went smoothly Ben drove the truck and I kept an eye on the tower. The loops of rebar were fairly long, and we had a bit of concern that the metal might fatigue if they were bent back and forth. We cut the old loops and made shorter ones from them and welded them back to the pipe. The tower was only up for one year, but I guess because it was located so near to the ocean, it showed considerable corrosion. At least two of the cables utilized scrap, used wire rope that was in terrible condition. These were the side anchors.

As we were on our way to lower the tower we ran into these guys who had been out to collect lunch. There is plenty of food just for the taking on this island. Seafood, fruits and vegetables galore.

A guy anchor before shortening.

Mr. Fotofilli cutting one of the guy anchors.

That looked like a lot of corrosion to me for only having been in the air for one year.

The cables and connectors were similarly corroded.

We removed the blades, and painted over the generator, the tower, the cables, and the anchors to try to slow the rate of corrosion. Ben set about shortening the blades.

Painted generator.

The tower, connectors, and even the cables got a good coat of paint. Since we only had this rust color paint, everything is the same color.

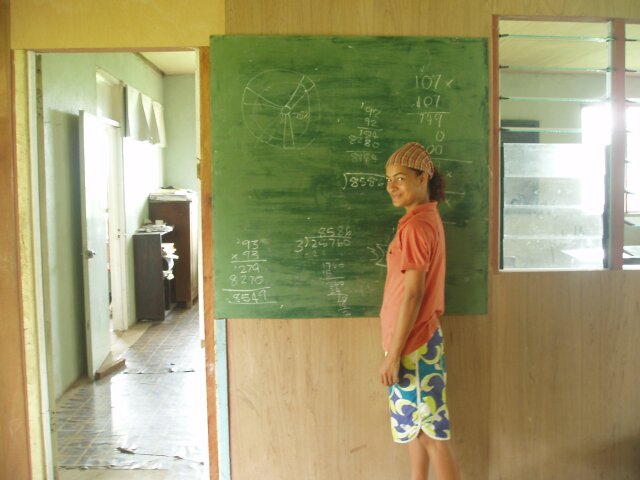

In the past, the machine could not be shut down, and would spin up in strong winds, even when shorted. Ben cut about 6 inches off of the blades after having Moana, the Fotofilli's daughter, do a chalk board full of calculations, I think to check her math skills.

Ben's photo of Moana calculating how much to cut off of the blade to reduce the swept area by 25%. She appears to be a good student. I hope she is able to go to college, I suspect very few of the island's residents do. Many migrate to the main island, but without skills to get higher paying jobs they can get stuck at the low end of the wage scale. She may be lucky, in that her parents intend to find a way to send her to college. With knowlege comes the ability to raise the standard of living, whether living on the island here, or elsewhere.

The shortened blade with a curved tip. The mill appeared, subjectively at least, to run much more quietly.

We re-assembled the mill and started to raise it. One of the side cables had too much tension in it, especially with the shortened loops. The side cables were of the wire rope that was in bad shape. It snapped about half way up. Fortunately we were able to lower the mill back down without incident. There was just enough slack to splice this cable. We had to make two sheet metal shields to protect the cable through the eye bolts. Another fun task without power tools. Once we had those made, it was time to assemble the splice. It was at that point, making the new loops that I realized just how bad of shape the cable was in. Some of the strands in the cable broke just from making the new loops. We raised the mill with the splice. We arranged to have new wire rope shipped out to the island. I received information that it had arrived, and hopefully it has already been installed for those side cables. We had to disconnect a couple of phone wires to the teachers quarters to lower the mill, and it also blocked most of the pathway by the side of the school, but in hind sight we probably should have left it lowered until the new cable arrived.

We raised the tower back up and leveled it as best as we could.

Adjusting the guys. This was done for each set of guys. My thumb which I smashed up a bit with a hammer my first day there appears to have healed up pretty nicely. Ben adjusted the turnbuckles to plumb the tower on each axis.

The wind turbine back up and in place. You can just see the splice near the top of the top cable nearest the left of the tower.

That concluded our work on the computer lab. As for the unused workshop, we gathered most of the remaining tools and took them to the Fotofilli's. The plan is that with the sale of small lighting systems made from the 10 Watt panels, plus the equipment already on hand, a small workshop can be constructed that will be overseen by Mr. Fotofilli for the benefit of the islands residents. The seed has been planted, and hopefully it will grow.

On Saturday afternoon, Ben insisted I go for a boat ride around the island with Mr. Fotofilli to see the sights of the island. I didn't take my camera because after breaking the phone I didn't want to ruin it. I should have taken it though. I got to see some pristine islands, and wild life. Some of the islands were undercut by the waves. I saw a giant sting ray, literally a flock of fruit bats and other assorted wild life. A blue green lagoon that looked like it would be perfect for swimming with small secluded beaches that had not been grown over with mangroves. It was a wonderful trip. Should you make it out to Moana's Beach House there, make sure you have him take you on a boat trip, and take your camera.

On Sunday we flew out from the airport on the island. This grass strip is the only airport there.

Vanua Balavu Airport. This is the Air Fiji plane we flew out on.

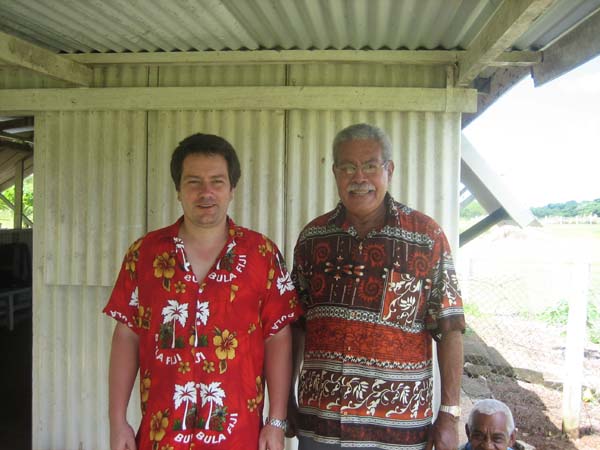

While waiting at the airport we ran into Laisenia Qarase, who was the elected Prime Minister of Fiji until the military coup that deposed him in December of 2006. He is a resident of Vanua Balavu. He thanked us for helping out on the island, and pointed out some touristy things to see on the northern route we were taking across the main island. Could I look any more like a tourist?

I was sad to board the plane leaving the island, but our time there was up. With the exception of the equipment and the airfare, the trip was not that expensive. We had no hotel bills and very little was spent on food as most was supplied. Everyone we met was nice and polite. Hopefully our trip there will benefit the people of Vanua Balavu. It was an experience that I will never forget. I hope to try something like this again next year.